How to correctly use concave and mantle of cone crusher at job site

Nov 03, 2025Using the mantle and concave involves far more than simply pressing the start button; it encompasses the entire process, including CSS adjustment, feeding, and monitoring, etc.

1. Pre-Start up Checks

Liner Tightness: Ensure the wear liners on the mantle and concave are securely installed and not loose. Loose liners can lead to breakage or accelerated wear.

Chamber Cleaning: Check the crushing chamber for any residual material or foreign objects (e.g., tramp metal, tools). The crusher must be started empty.

Lubrication System: Check that the lubricating oil is sufficient, the oil circuits are smooth, and the oil temperature is normal. Proper lubrication is the lifeline for the mantle bearing and eccentric sleeve.

2. Feeding Operation - The Key!

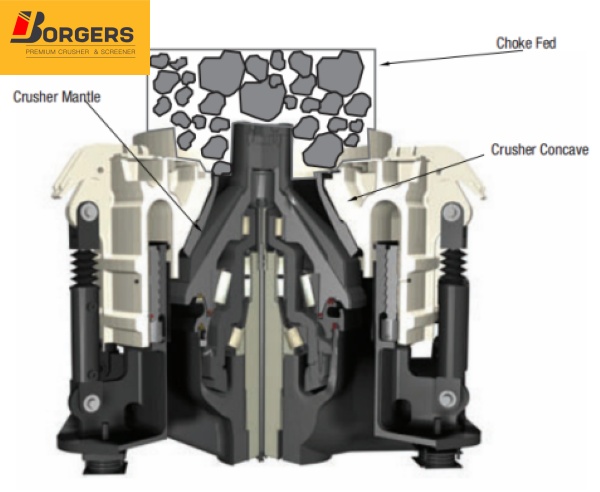

Choke Feeding: Feeding must be uniform, continuous, and ensure the material is evenly distributed within the crushing chamber to form a "material bed" or "rock shelf".

Benefit: This promotes compression and attrition between the rock particles themselves. This effectively protects the mantle and concave liners by reducing direct metal-to-metal contact, thereby extending liner life.

Cone crushers must be choke fed at all times to optimize performance. Material should always be filled up to above the mantle nut. As shown, to ensure a full choke fed cone. Choke feeding ensures best attrition crushing in the chamber and equal loading all round avoiding an 'out of round' wear pattern on the liners.

Our cone crushers have automated control system to keep the cone choked by increasing feeder speed when the cone is empty and decreasing the feeder speed when the cone is full.

Incorrect Operation: Inconsistent and intermittent feeding leads to uneven liner wear, reduced production capacity, and unstable product gradation.

Pre-Screening: It is recommended to pre-screen the feed material to remove a portion of the already qualified fines and powders (Note: Do not remove all fines). This improves crushing efficiency and prevents "over-crushing" and choking.

No Tramp Metal: Strictly prevent metallic foreign objects (e.g., shovel teeth, drill bits) from entering the crusher. This can cause severe damage to the mantle and concave liners, and may even lead to catastrophic failures such as main shaft breakage.

3. Discharge Setting Adjustment & Product Size Control

This is one of the core operations in "using" the mantle and concave, aimed at controlling the product discharge size.

Adjustment Principle: Change the minimum distance between the bottom of the mantle and the bottom of the concave (i.e., the discharge opening) by raising or lowering the mantle.

Hydraulic Adjustment: Most modern cone crushers utilize a hydraulic system. By operating the hydraulic power unit, the mantle assembly is raised or lowered, thereby changing the discharge setting. This allows for adjustment even under load, which is very convenient.

Key Operational Points:

Ensure the discharge opening size is consistent on both sides during adjustment to guarantee uniform product discharge.

Regularly check the discharge opening size, as it will increase (resulting in a coarser product) as the liners wear.

4. Operation Monitoring

Sound: Normal operation produces a steady rumbling sound. Immediately stop the crusher to inspect if severe impacting or metallic grinding noises occur, as this may indicate tramp metal or loose liners.

Current: The main motor current is a key load indicator. Excessively high current may indicate overfeeding, excessively hard material, or a mechanical fault; excessively low current may indicate insufficient feed.

Lubrication System: Continuously monitor oil temperature and pressure. The return oil temperature should generally not exceed 55-60°C, and oil pressure must remain within the set range.

Vibration: Excessive vibration typically indicates issues such as imbalance, loose foundations, or internal wear.

For more information about Borgers' mobile cone crushers and services, please visit our official website or contact Borgers service team.